Capabilities

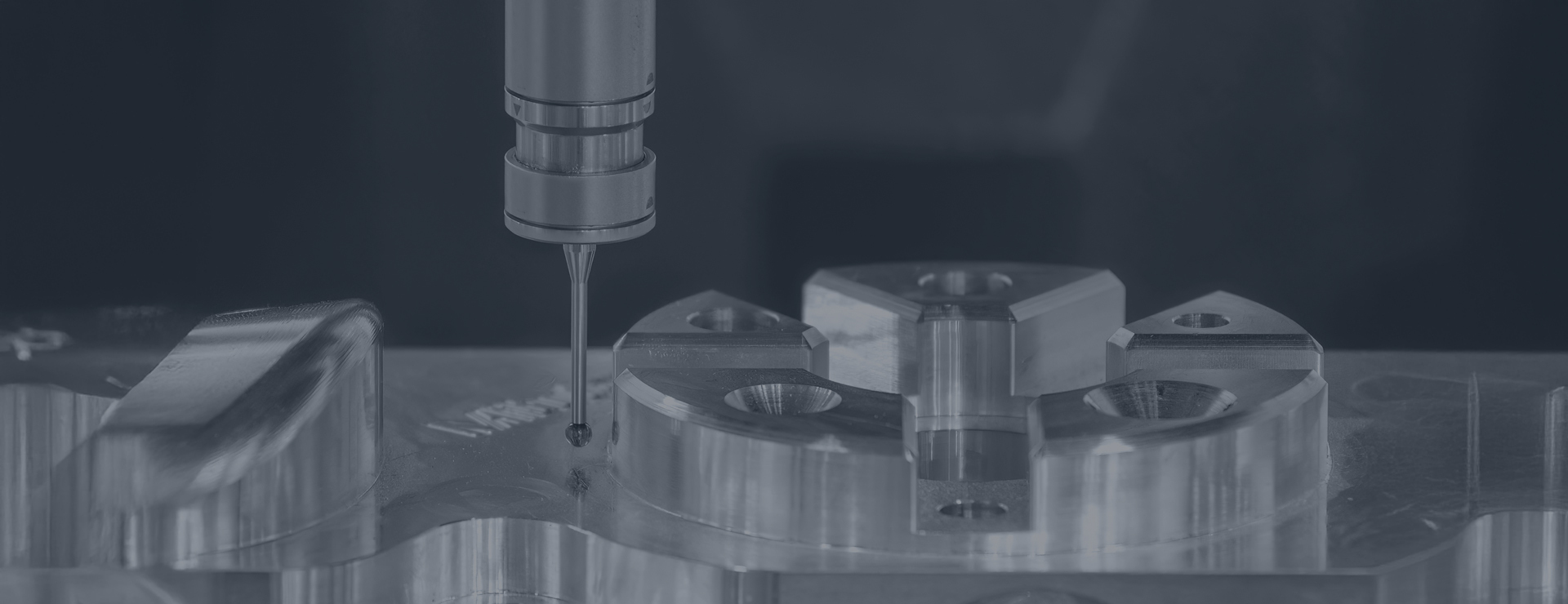

Our capabilities are built around, Quality, Efficiency, On-Time Delivery and scalability. We combine the latest in second generation machine tool technology and automation from DMG MORI and DN Solutions with advanced CAM from OPENMIND Hypermill and Hexagon Esprit to deliver consistent high accuracy machining and turning across a range of complex components.

Our automated production cells enable lights out manufacturing on a 24/7 basis, allowing us to scale output seamlessly whilst reducing lead times and labour costs.

We work confidently across a wide range of metals, including aluminium, stainless steel, titanium, Inconel and tool steels. This versatility allows us to support critical applications across aerospace, defence, medical and space sectors.

We program using Openmind Hypermill and Hexagon Esprit CAM software, giving us full control over complex geometries and tight tolerances. Our machines routinely hold tolerances within ±0.01mm, delivering exceptional surface finishes and repeatability at any volume.

With full automation and 24/7 production, we can flex to meet demand without compromising quality. Every component is inspected using advanced metrology equipment, with in-process and final checks built into our workflow. This ensures every part meets your specification, no matter the scale.afety in medical devices, our role is to deliver trusted engineering solutions that perform under pressure.

Get in Touch

Whether you need support on a current project or want to explore what our engineering capabilities can achieve for you, our team is here to help. Reach out today to start the conversation.

Get in Touch